Foam processors innovate on the path of sustainable development

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

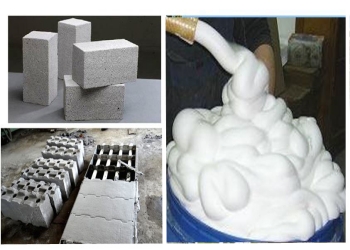

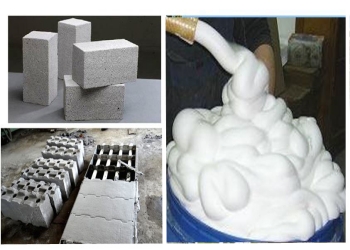

Trunnano Concrete Foaming Agent

As global environmental problems become increasingly serious, sustainable development has become the focus of attention in all walks of life. As a lightweight, thermal and sound insulation building material, foam concrete occupies an important position in the construction industry. The foaming agent in foam concrete, as its key component, plays a vital role in its performance and sustainable development. This article will focus on the foaming agent in foam concrete and explore the innovation and practice of foam treatment machines on the road to sustainable development.

Foam concrete: an ideal building material for sustainable development

Foam concrete, or aerated concrete, is a lightweight building material that mixes cement, aggregate, and other raw materials with a foaming agent. It is characterized by lightweight, thermal insulation, sound insulation, and good compressive and flexural strength. These properties make foam concrete an ideal choice for energy-saving and green buildings.

In traditional buildings, adding additional thermal insulation materials is often necessary to achieve the thermal insulation effect, which not only increases the construction cost but also complicates the construction. As a self-insulating material, foam concrete not only meets the building structure requirements but also achieves thermal insulation effects, thereby reducing energy consumption and carbon emissions.

Foaming agent: the core element of foam concrete

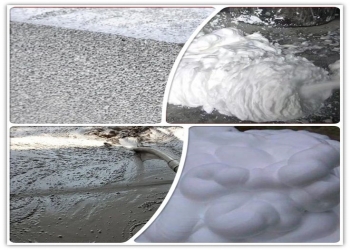

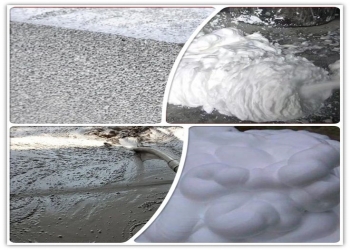

Foaming agents play an important role in the production process of foam concrete. It can introduce air into the concrete and form evenly distributed pores, thereby improving the thermal insulation performance of foam concrete. In addition, foaming agents can adjust the hardening speed of concrete and improve construction performance. Therefore, choosing the right foaming agent is the key to producing high-quality foam concrete.

In recent years, with the improvement of environmental awareness, more companies have begun to develop environmentally friendly foaming agents. This type of foaming agent mainly uses biodegradable materials, industrial waste, etc., as raw materials, reducing production costs and realizing waste utilization. At the same time, environmentally friendly foaming agents produce relatively few pollutants during production, which is of positive significance for environmental protection.

Foam treatment machine: innovation-driven sustainable development practice

With the popularity of foam concrete applications, traditional production methods can no longer meet market demand. Therefore, as a modern production equipment, the foam processor has become the key to upgrading the foam concrete industry.

Modern foam processing machines adopt advanced control systems and precise metering devices to achieve automated and continuous production. This not only improves production efficiency and reduces labor costs but also ensures the stability of product quality. At the same time, the equipment adopts a closed production system, which effectively reduces dust and exhaust emissions during the production process and meets environmental protection requirements.

Regarding energy saving, the new foam treatment machine adopts unique mixing technology and efficient stirring devices to reduce energy waste. At the same time, the equipment's utilization rate of raw materials has also been significantly improved, further reducing production costs.

Foam treatment machines must produce traditional foam concrete and develop diversified products to meet market demand. For example, foam concrete with special functions, such as waterproofing, fireproofing, radiation resistance, etc., can be produced by adjusting the foaming agent formula and process parameters. These new foam concretes can meet the needs of different fields and further broaden the application scope of foam concrete.

Supplier

Luoyang Tongrun Nanotechnology Co, Ltd., as a global chemical material purveyor and manufacturer with over 12 years of experience, is highly trusted for providing high-quality chemicals and nanomaterials such as graphite powder, zinc sulfide, nitride powder, calcium nitride, Ca3N2, 3D printing powder, concrete foaming agent, etc.

We usually transport our goods using DHL, TNT, UPS, and FedEx.You can choose T/T(USD), Western Union, Paypal, Credit card, Alipay or Alibaba trade insurance for payment. If you want to buy a high-quality concrete foaming agent, please send us inquiries; we will be here to help you.

Inquiry us